© 2024 FineFoods

Innovation/ Continuous Improvement

Improvement: Continuous, Cross-Sectional, Intensive

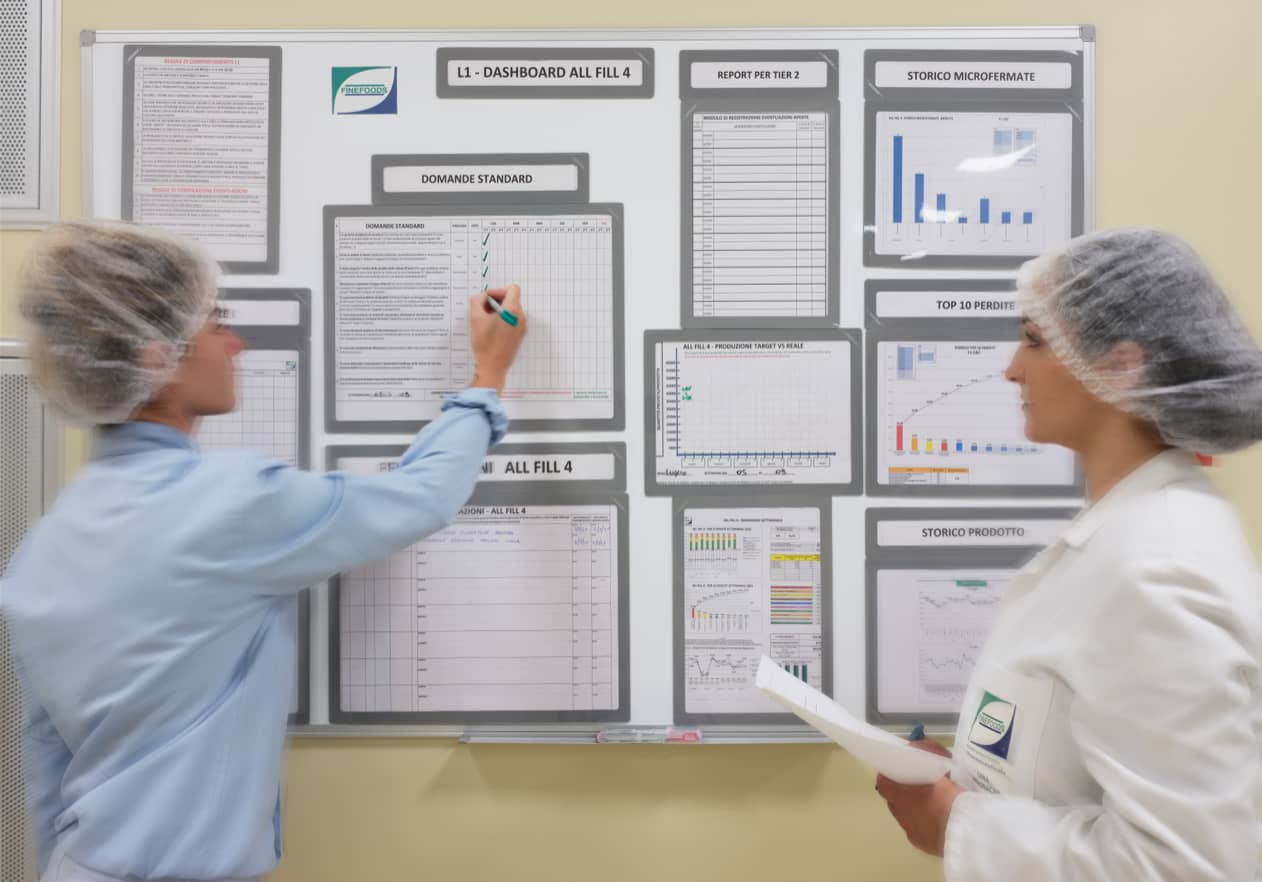

Continuous Improvement in every department is an essential part of Fine Foods’ Competitive Strategy. Numerous Continuous Improvement projects help us to intercept and implement improvement activities that constantly and concretely increase our competitiveness.

The ideal partnership between Problem Solving and Lean Thinking

With the Continuous Improvement Programs, at Fine Foods improvement never stops:

- Lean Mindset to simplify and optimize the resources

- Unrelenting assessments to discover improvement opportunities

- A flexible and proactive organization, with roles and responsibilities shared and clearly defined

- A dynamic approach to innovation, to improvement and to problem solving

- Strict cooperation with Controlling to guarantee economic sustainability of programs

- Cross-functional participation of all company’s departments

- Support the errors: we learn from our mistake

Collaborazioni sinergiche e produttive